Analytics Insight predicts that AR in the manufacturing industry to touch US $2.8 Billion in 2023.

This is a future prediction, but what about the current situation?

Has any company adopted Augmented Reality?

Well, there are companies like Honeywell Aerospace that have adopted Augmented Reality.

Post adopting AR, the company has witnessed a massive 50% reduction in training time, null human errors, and a 30% improvement in productivity.

This is just a story of one company; there are many others that we will discuss in this article.

Besides, we will also shed some light on how Augmented Reality is changing the manufacturing industry.

If you are thinking of leveraging Augmented Reality, now is the right time to invest in such cognitive technologies.

But what is it and how does it work?

Let’s delve into this article and know more about it.

What is AR in the Manufacturing Industry?

Augmented Reality in the manufacturing industry was a prediction a few years ago, which is now happening.

In fact, most manufacturers have even adopted Augmented Reality in their units to overcome the challenges they were facing, such as:

- Complicated product design and development

- Heavy manufacturing costs

- Maintaining quality

- Safety protocols

- Training and onboarding.

So, these are the changes you can expect with Augmented Reality.

Want to adopt these changes in your manufacturing unit as well, talk to an augmented reality app development company professional.

Discuss your idea and get the quote now.

Now that you know what Augmented Reality is, let’s discuss how it impacts manufacturing industries like yours.

How Augmented Reality Impacts the Manufacturing Industry?

Augmented Reality has contributed a lot to the manufacturing industry.

Take a look at what majority of tasks Augmented Reality has streamlined, and how AR is changing manufacturing processes.

AR for Training and Onboarding in Manufacturing

Augmented Reality makes the steep learning curve at the manufacturing unit easier for the new joiners.

AR creates a safer environment in hazardous conditions and quickly trains new joiners.

For example, Ather, with the help of an AR-based application, trains new employees with systematically created guides, manuals, and documents that are essential for training.

AR simulates real-world situations in a semi-virtual way.

Besides, AR apps offer feedback on employee performance so that the trainees know their areas of improvement.

If you’re thinking of having an AR-based app for yourself, the first thing you should know is how much does it cost to build an augmented reality app.

AR for Shop Floor Issues & Resolution

Manufacturing units always have shop floor issues that aren’t addressed and resolved on time.

But with AR in place, these issues get notified timely to the maintenance team so that they can resolve them without negatively impacting the production processes.

AR for Maintenance

Machine breakdown and downtime are significant issues in the manufacturing industry.

It directly impacts income and revenue.

And despite hiring skilled professionals, they will at least require to go through the manuals and documentation once.

But with augmented reality, waiting and downtime in the manufacturing industry have become a thing of the past.

AR evaluates and identifies potential flaws in seconds, which once was a task of hours when performed manually.

And not only detection, but AR also offers a long-term solution so that the problem doesn’t arise again and you stay worry-free.

Ultimately, AR contributes to reducing recurring maintenance costs and boosting productivity and efficiency.

AR for Product Development

When it comes to prototyping a product, it requires hefty capital, time, and huge professional expertise.

And it should be perfect to beat the competition and meet technological trends, customer expectations, and environmental regulations.

But with the AR, the time to market and requirement of the resources have become minimal. AR speeds up the process of:

- Conceptualization

- Development

- Introducing the product to the assembly line

- Meeting safety standards

Your product development or prototyping cost could only be saved if you build an AR-based mobile application.

Go through the linked article on the mobile app development cost and connect with us.

Just like AR speeds up your manufacturing processes, our proficient developers would also deliver AR applications in no time.

AR for Safety Manufacturing Unit

Workers in manufacturing units are at constant risk of injuries or accidents.

If you are one of those who give priority to employee safety, then employing AR would be the best decision.

It analyzes and alerts employees to maintain safety standards.

AR for Spatial Computing

Spatial computing makes use of Augmented Reality to create an interactive experience of the real world in a digital way.

Users interact with holograms and 3D models of the data and information in a more intuitive method by using their hand gestures, touchscreens, and voice commands.

In the manufacturing industry, you can leverage Augmented Reality to know the nitty-gritty about a specific material.

Moreover, you can even take a look at the finished product to check for the flaws that were addressed during the production process.

AR for Assembly

With the use of Augmented Reality, you can make the complicated assembly process easier and smoother.

Assembling machines is one of the most time-consuming and complex tasks but with the use of AR, the operator can assemble it through visual assistance.

3D images or animations instruct the operator to assemble the machines in a stepwise method.

AR could even manage to guide you through each location of the parts and make you fix it.

Moreover, it even notifies you when an entire machine is built.

The benefits of AR for assembly are as follows:

- Efficiently completed tasks

- Elimination of potential flaws

- Rectification of quality issues

AR for Quality Control

AR allows the collaboration of employees that helps to fasten up the quality check processes.

The new generation technology meticulously inspects components, visualizes the flaws, and offers guidance on how to resolve them.

Most of the giant manufacturing companies have already set up Augmented Reality to inspect, detect, and rectify flaws.

AR for Customer Service

Enhancing and overwhelming customer service is one of the ways to win your customers’ hearts.

With the help of AR, you can walk through your customer’s location and instruct them about the potential flaws and step-wise fixing process.

These are potential impacts or benefits of Augmented Reality in the manufacturing industry.

Now, we will walk you through some real-life examples to understand how Augmented Reality has already brought drastic changes in the manufacturing industries.

Use Cases of Augmented Reality in the Manufacturing Industry

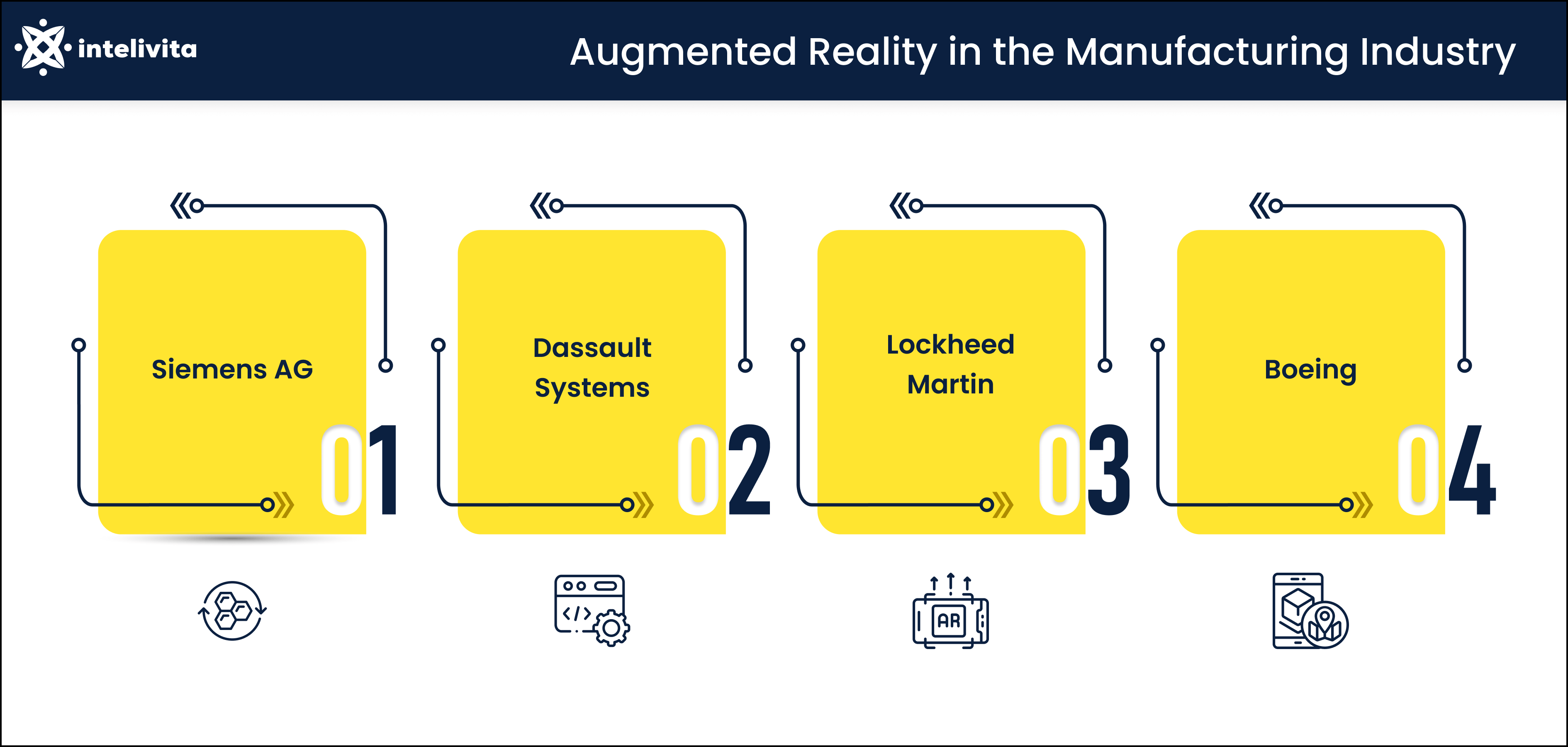

Siemens AG

Siemens AG offers Augmented Reality solutions to improve services.

One such masterpiece is AR-enabled goggles that monitor performance and guide on repairing and assembling all the components.

Dassault Systems

Since this company operates in 3D designs and product engineering, the company’s use of AR is massive.

The 3D experience platform makes use of AR headsets or tablets to interact with essential information.

Lockheed Martin

This company adopted Augmented Reality to boost the speed and accuracy of the manufacturing processes.

With AR, engineering personnel would identify flaws and fix them before they become severe.

Boeing

Boeing uses AR to find the location parts. Besides, cognitive technology also instructs engineers at Boeing to assemble aircraft.

Adopting AR benefits a lot to Boeing since they noticed a reduction in assembly time, elimination of errors, and improvement in productivity.

How to Decide the Implementation of Augmented Reality at Your Manufacturing Unit?

Phase 1: Identify Time-consuming or Resource-requiring Areas

Identify which of your manufacturing areas requires speeding up the process or demanding more manpower than usual.

Phase 2: Build a Prototype

Once you identify the area, build a prototype of AR to test the waters.

This phase helps you to identify the possible problems even in AR, which you can rectify in the development phase.

Phase 3: Design & Develop

Once the prototype is finalized, start looking for an AR app development company to build custom software to make the desired features available at your demand.

Phase 4: Teach Your Employees

Once the software is built, teach your employees how to operate them and get started.

Phase 5: Track Its Performance

Keep an eye on the AR software and look out for possible performance metrics.

Any flaw you identify, notify the dev team and get it fixed.

Conclusion

Augmented Reality (AR) is transforming the manufacturing industry by improving numerous manufacturing processes, effectiveness, and quality.

The manufacturing process can be agile and error-free when workers have access to real-time information.

Moreover, AR can enhance customer experience, simplify onboarding and training, and increase safety.

We may anticipate even more developments in the manufacturing industry as businesses continue to leverage Augmented Reality, which will boost output and competitiveness.

Given all of the advantages of AR, it is certain that this technology will become more and more crucial to the manufacturing sector in the years to come.